LADICIM leads the Cantabrian project that will apply AI to reduce emissions in industry, energy and transport

The INTELEST project, financed by the Government of Cantabria with European funds, has the collaboration of companies such as GSW and Rocacero, research centers such as IHCantabria and sectoral organizations such as MAFEX

Climate change, driven by increases in greenhouse gases due to human activity, is causing global warming, climate disruption, melting polar ice, rising sea levels, and more frequent and severe extreme weather events. These phenomena have adverse consequences on ecosystems, biodiversity, food security, water resources and human health, presenting a significant challenge for sustainable development and global well-being.

The INTELEST project, promoted by the Materials Science and Engineering Laboratory (LADICIM) of the University of cantabria, aims to develop various tools based on Artificial Intelligence (AI) that allow reducing greenhouse gas (GHG) emissions in strategic sectors such as transportation, energy and industry. The ultimate goal of the project is the transfer of the scientific and technological knowledge generated to the productive and industrial fabric, focusing on the Cantabria region, to optimize industrial processes, improve energy efficiency and promote sustainable transport practices, thus contributing significantly to the global fight against climate change.

INTELEST is a project financed by the Ministry of Industry of the Government of Cantabria, through the FEDER 2021-2027 program, under the line ‘Aid program for research projects with high industrial potential of technological agents of excellence for industrial competitiveness (TCNIC)’.

“The project is part of a knowledge transfer strategy that seeks to directly benefit the productive and industrial sector of Cantabria, providing it with advanced tools to face the challenges of climate change,” explains the emeritus professor. Federico Gutiérrez-Solana, Project coordinator. “All this through the adaptation and application of knowledge generated in almost four decades of research at LADICIM, along with the implementation of cutting-edge technologies in the modeling and optimization of industrial processes, transportation infrastructures and energy generation systems.”

A project with 4 lines of investigation

INTELEST It is based on a premise: AI offers a set of tools with great transformative potential, capable of offering innovative solutions to complex and multifaceted problems such as climate change. To focus these capabilities, the strategic sectors of industry, energy and transportation were selected, both for their significant contribution to global greenhouse gas emissions and for their potential to implement more sustainable and efficient practices.

By focusing on three different sectors, the INTELEST project is structured into four lines of research in which LADICIM accumulates extensive experience and knowledge. In the last five years alone, different researchers from the Laboratory have published more than 100 articles indexed in the Journal Citation Reports (JCR) related to these four lines of work.

“The Laboratory has experience in the application of AI tools in some of its research areas, but INTELEST represents a before and after in this sense because it involves already applying AI widely in all our lines of work,” says the professor emeritus Gutiérrez-Solana, founder of the Laboratory more than 40 years ago. “Our research is highly oriented towards the transfer of knowledge, especially to the field of engineering in sectors such as transportation or energy, and the integration of AI in all our activities will further enhance our ability to serve the industry. On the other hand, INTELEST will also allow us to generate a positive impact at other levels, since it will facilitate the reduction of consumption and emissions. This will not only improve the competitiveness of Cantabria companies, it will also help combat climate change.”

Line 1: Optimization of energy consumption in steel production

The first line of work of the INTELEST project is supported by the historical collaboration between LADICIM and Global Steel Wire (GSW), European leader in the manufacture of high added value steel and one of the main production centers located in Cantabria. This permanent collaboration has always been aimed at reducing energy consumption in industrial processes, a strategic objective for GSW.

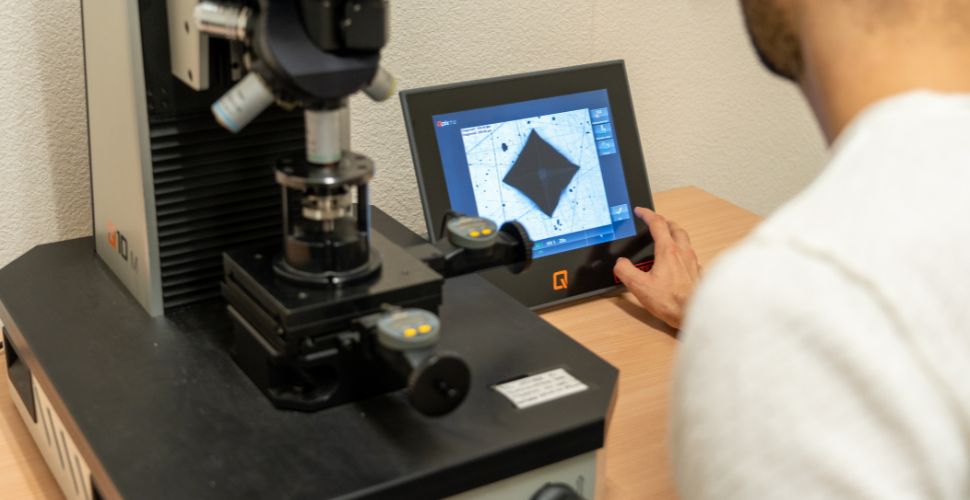

INTELEST will allow an important leap in this collaboration process between University and company. Through the use of advanced numerical simulation tools and Machine Learning algorithms, a team led by the LADICIM professor Diego Ferreño will develop a digital twin of the induction furnace used in the steel billet manufacturing process, in order to optimize its operation and reduce the energy consumed.

Specific objectives include the design of AI algorithms to establish efficient heating strategies, the development of Finite Element models to predict billet temperatures, the creation of a virtual laboratory to generate synthetic samples, and the exploitation of these models to optimize the manufacturing process.

Line 2: Prediction of embrittlement of steel in nuclear power plants

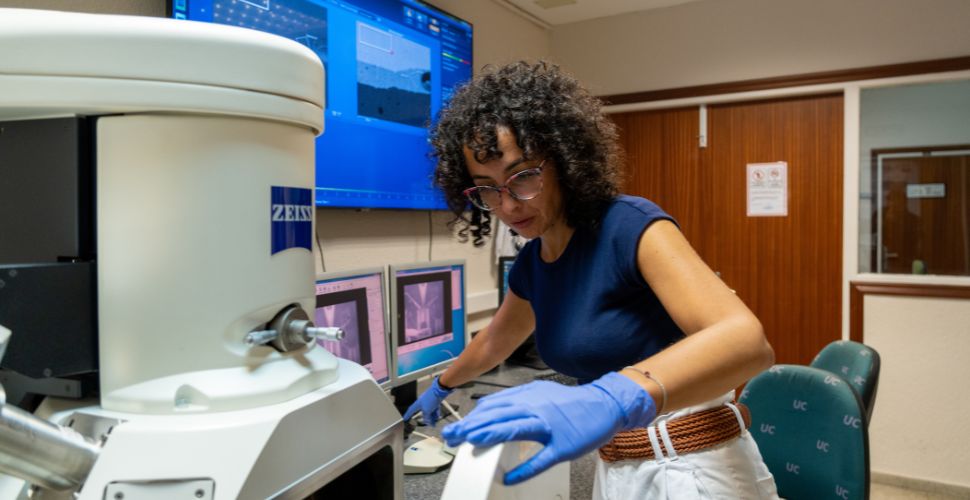

This line of research, focused on the energy sector, is supported by the recurring collaboration between LADICIM and international organizations such as the American Society for Testing and Materials (ASTM), he Electric Power Research Institute (EPRI) and the Energy, Environmental and Technological Research Center (VILLAGE). These collaborations have allowed LADICIM to access the most complete database worldwide regarding the embrittlement experienced by nuclear reactor vessels under operating conditions. A unique resource that positions the team led by Professor Diego Ferreño to address the challenge of the embrittlement of vessel steels, crucial for the safety and useful life of nuclear fission plants, through the development of predictive models based on Machine Learning.

This research aims to develop predictive models that determine the degree of embrittlement suffered by the steels of nuclear reactor vessels due to neutron irradiation, in order to ensure the long-term operation of nuclear fission plants. Efforts are aimed at training and validating algorithms that support the identification of safe operating conditions, the design of predictive monitoring programs and the improvement of the structural integrity of critical components in the nuclear sector.

Line 3: Development of high-performance concrete for offshore wind power

INTELEST’s third line of research focuses on the development of innovative solutions for the generation of offshore wind energy, specifically through the construction of floating wind platforms made of concrete instead of steel. The initiative arises in response to the challenges presented by the corrosive marine environment and the mechanical demands of wind and waves, which negatively affect the durability and efficiency of traditional steel structures.

The existing collaboration between LADICIM, the Institute of Environmental Hydraulics (IHCantabria) and the company specialized in precast concrete Rocacero underlines a commitment to innovation in construction materials and techniques that improve the sustainability and performance of infrastructure intended for the generation of renewable energy at sea.

This line of research, led by the LADICIM professor Isidro Carrascal, will be dedicated to the development of high-performance concrete for use in floating offshore wind platforms. An innovation that seeks to replace steel with prestressed concrete to improve the durability and resistance of these structures against the adversities of the marine environment.

The project applies Artificial Intelligence algorithms to optimize the composition of the concrete, ensuring that it meets specific requirements for workability, structural integrity and durability.

Line 4: Predictive maintenance of high-speed railway infrastructure

The background of this line of research revolves around the experience accumulated by LADICIM in previous collaborations focused on the optimization of components of the high-speed railway superstructure. For more than three decades, the Laboratory has developed research to improve the interconnectivity and sustainability of rail transport in Cantabria, collaborating with regional, national and international companies such as Redalsa, MAFEX, Pandrol and the Administrator of Railway Infrastructures (ADIF), among others.

This line of work, led by the professor and director of LADICIM José A. Casado, focuses on the design of tools for the predictive maintenance of high-speed railway infrastructure. Among them, the application of numerical modeling by Finite Elements and Artificial Intelligence algorithms to optimize maintenance management, moving from a reactive or preventive approach to a predictive one.

Its objective, therefore, is to predict the mechanical behavior and damage in the elements of the railway superstructure (such as ballast, sleepers, and fastening components) under operating and aging conditions. The aim is to develop a holistic model that simulates the behavior of the road in real conditions and Machine Learning algorithms to infer the level of damage of the elements from inspection data. An approach that will reduce operation and maintenance costs, in addition to improving the safety and reliability of high-speed rail transport.

The INTELEST project, through an innovative approach that facilitates the transfer of knowledge and the application of advanced Artificial Intelligence and numerical simulation technologies, will improve the competitiveness of collaborating companies. By optimizing processes, reducing operational and energy costs and improving efficiency and operations, the companies involved will be able to position themselves more advantageously in the market. Furthermore, its future positioning will also improve thanks to the added value of its adaptation to cutting-edge technologies and the adoption of sustainable practices. Benefits that can later be extended to other companies and industrial sectors.

This entity has received a grant co-financed by the European Regional Development Fund through the ERDF Operational Programme 2021-2027 of Cantabria through the line of subsidies ‘Aid for research projects with high industrial potential of technological agents of excellence for industrial competitiveness TCNIC’.