LADICIM leads the concrete durability tests in the Isobara project

The research, in which IHCantabria and Seaplace also participate, seeks to standardize a floating concrete platform for offshore wind energy

The project Isobara, which seeks to standardize a floating concrete platform for offshore wind energy, is entering a crucial phase of durability testing. At this stage, the Materials Science and Engineering Laboratory (LADICIM), a specialist in the study of behavior of concrete in the marine environment (SEACOND Project), will lead the necessary tests to evaluate the durability, manufacturing and technical-economic viability of the material, with the aim of guaranteeing its resistance and suitability for marine environments.

The Isobara project aims to create a standardized floating concrete platform for offshore wind energy. This platform, conceived under an industrializable technological concept, seeks to be competitive in construction costs and adaptable to various maritime conditions. The final objective is to optimize the behavior of the turbine-tower-platform-anchoring system system throughout its useful life, offering a solution that can be mass produced for global use.

The importance of Isobara lies in the need to harness offshore wind potential in deep waters, inaccessible to traditional fixed structures. The floating platform developed by the project will allow access to these resources, promoting the decarbonization of the European energy mix and contributing to the climate objectives for 2050.

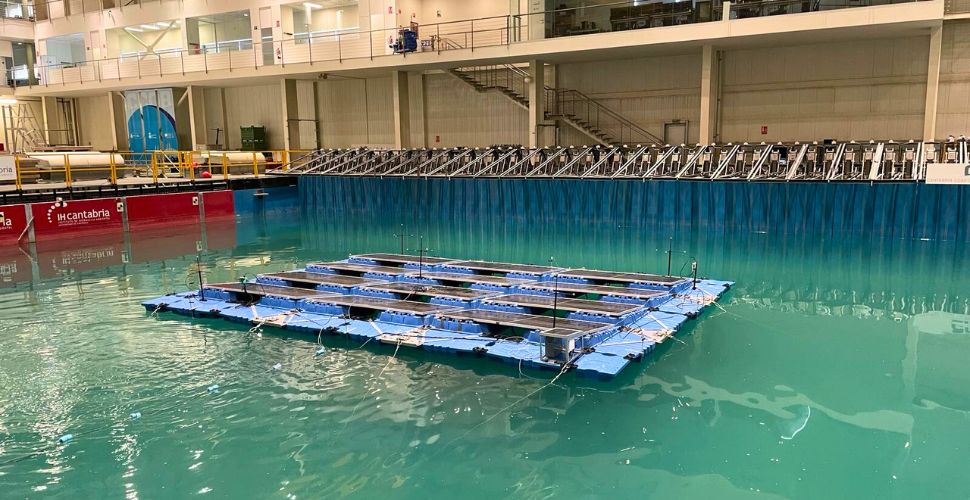

Test at El Bocal

LADICIM, together with the company specialized in offshore engineering Seaplace and the Institute of Environmental Hydraulics of the University of Cantabria (IHCantabria), make up the Isobara research team. The project, financed by the Ministry of Science, Innovation and Universities through the State Research Agency, and by the European Union, with NextGeneration EU/PRTR funds), is now in a Durability testing phase at the El Bocal facilities (Santander), which manages the Components Technology Center (CTC).

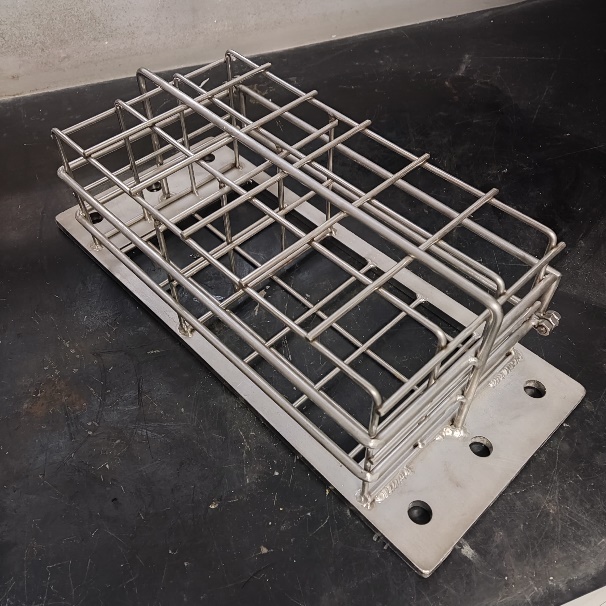

The tests consist of exposure of concrete specimens to the action of seawater for prolonged periods with the aim of evaluating the strength of concrete and its ability to protect reinforcement in demanding marine environments.

Isobara seeks to standardize the design of a floating concrete platform to facilitate its mass production, thus reducing the costs of floating wind farms. By focusing on a common construction material such as concrete, the project seeks generate economies of scale and reduce construction and deployment costs, making offshore wind energy more competitive and accessible..

The Isobara project is aligned with the European Union strategy for a Low Carbon Economy and the objectives of the R5 Challenge – Climate, energy and mobility of the Public-Private Collaboration 2021 call. By developing a technology that expands the potential of offshore wind energy, Isobara contributes to the reduction of carbon emissions and progress towards a more sustainable energy system.

In the long term, Isobara is expected to consolidate the use of floating concrete platforms for offshore wind energy as a viable and competitive alternative. The technology developed could contribute to a significant increase in the installed capacity of deepwater offshore wind, reducing dependence on fossil fuels. Furthermore, Isobara’s solutions are expected to have a positive impact on the economy, generating employment in the renewable energy industry and driving innovation in the sector.