LADICIM and GSW join forces to optimize steel quality by controlling residual hydrogen

The H2ALAM project investigates how to improve the resistance and durability of this material by regulating the levels of the chemical element during its manufacturing

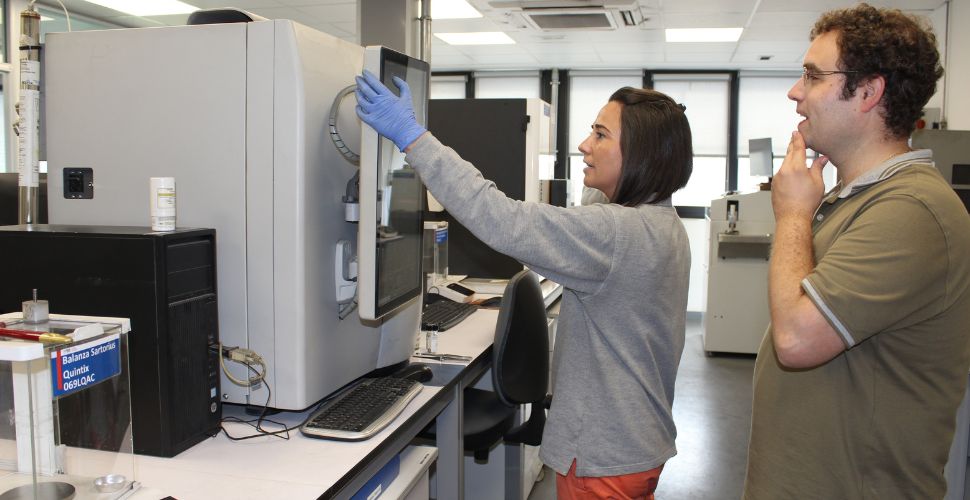

The Laboratory of the Materials Science and Engineering Division of the University of Cantabria (LADICIM) and Global Steel Wire (GSW) are developing the H2ALAM project focused on investigate the influence of residual hydrogen on steel during its manufacturing process. This new collaboration between the research center and the European high-end wire rod manufacturer aims to optimize the mechanical properties of steel and ensure its performance in industrial applications. The project, which is in its final phase, will contribute to increase the competitiveness of the steel industry.

Hydrogen that accumulates in steel during its manufacture can negatively affect its strength, which has driven this collaborative research to control and reduce its presence in the material. Through a detailed analysis of the rest times between production steps, H2ALAM seeks to identify the critical points at which this hydrogen must be released, thus ensuring that the steel is tough enough for its various applications.

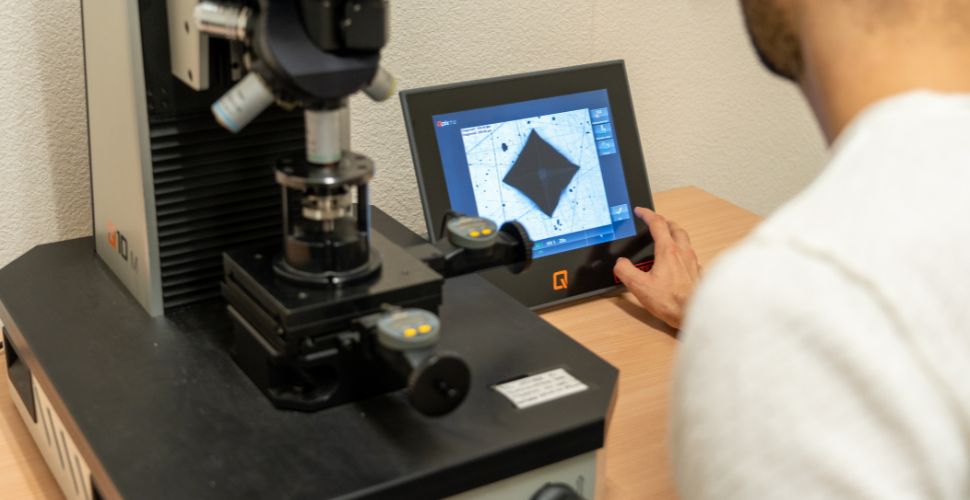

LADICIM, with more than four decades of experience in the simulation of aggressive environments to study the behavior of materials, is creating controlled environments to evaluate how hydrogen affects steel. For this, they use advanced techniques such as cathodic polarization. It consists of applying an acid solution and a platinum network to the steel under study, allowing different levels of hydrogen to be introduced into the material. The objective is to simulate real conditions of use to analyze how steel is affected by the presence of hydrogen, analyzing its response according to the concentration of this element in the material.

The H2ALAM project also aims to set a limiting hydrogen content, that is, the maximum level that steel can contain without compromising its quality. With these results, it is expected improve both the manufacturing process and the quality control of said material, increasing its competitiveness in the market.

H2ALAM is developed under the direction of two LADICIM researchers: the doctors Jose Alberto Alvarez and Borja Arroyo.