Composites

Characterisation techniques of plastics and composite materials

Production and recycling

LADICIM has an Arburg plastic injection machine, (model ALLROUNDER 221 K) of 350 kN of mold closing force and a spindle of 25 mm in diameter. The fuel transfer is equipped with a two-cavity steel mold to manufacture standardized B1 type test specimens according to EN ISO 527-4.

The laboratory equipment includes a Mateu and Solé soundproof mill, model 19/25 M5, 5, for recovering thermoplastic parts, crushing them up to a particle diameter of 6 mm for subsequent reinjection.

Rheological and abrasion characterisation

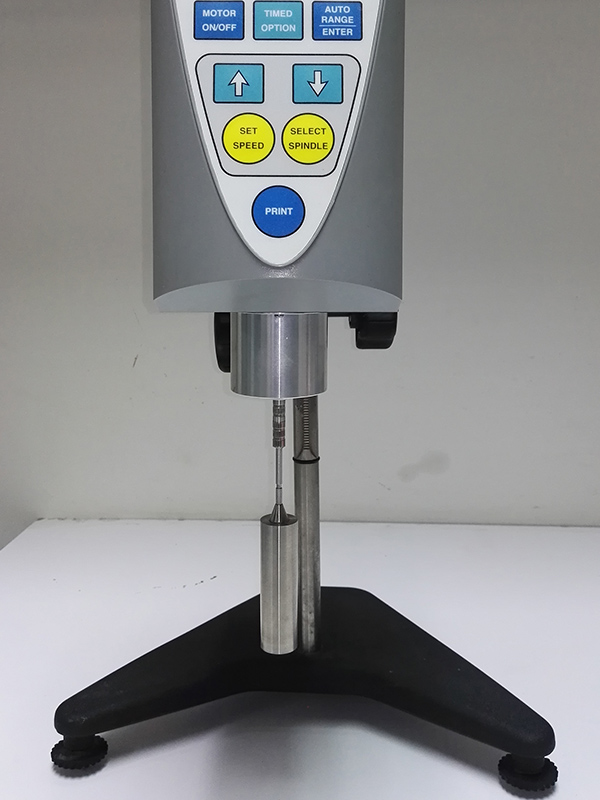

The laboratory has devices to measure the rheological behavior of polymeric materials. For this, LADICIM has an INSTRON Melt Flow modular equipment for the determination of mass flow index (MFR) and volume flow index (MVR) of thermoplastic materials and a BROOKFIELD digital viscometer, model LVDV-I PRIME, for the calculation of the viscosity of the fluid at different shear rates.

To evaluate the resistance of the surfaces to abrasion (by abrasion of abrasive wheels), a Taber brand Abrasimeter, model 5135 is available.

Mechanical characterisation

LADICIM has universal mechanical -static and dynamic- testing machines equipped with cells with variable load capacity (from 1250 N to 25 kN, usual range for polymer matrix components).

An IRISYS infrared thermographic camera to control the surface temperature of the specimens during dynamic tests is also among the measurement devices of the lab.

For dynamic impact tests, the laboratory has an INSTRON Charpy pendulum, model IMPACTOR II, equipped with two instrumented hammers, of 5 and 50 Joules, and a Visualimpact 0710.680MN1 software for the analytical treatment of results.