Metallics

Characterisation techniques of metallic materials

Conventional mechanical characterization

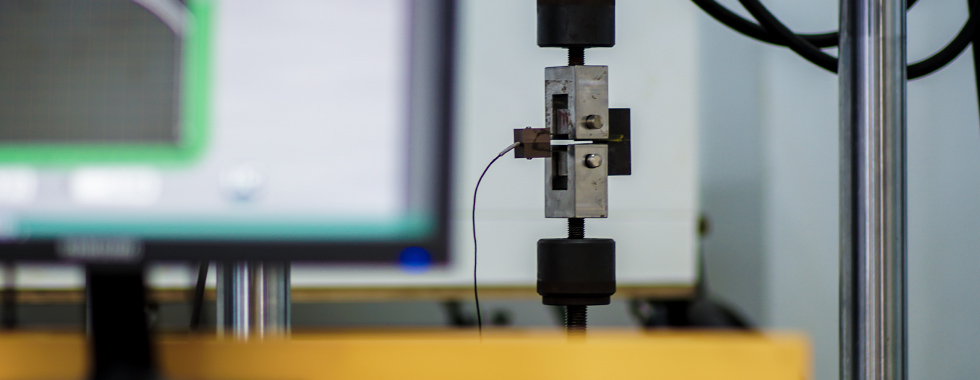

LADICIM has a set of universal mechanical testing machines that consists of load cells ranging from 2.5 kN (Zwick-Roell machine BT1-FR2.ST5.140) to 1000 kN (Instron-8505, with dynamic capacity) or to 1500 kN (Suzpecar-CME 150 machine, static loading). This equipment allows a wide range of tests such as tensile tests, bending tests or fracture tests of structural components to be performed. Some examples of elements usually characterized in LADICIM facilities and for which the laboratory is certified by ENAC are: reinforcing steel elements of concrete, sewage covering elements or components of the railway superstructure. LADICIM has also environmental chambers for performing tests in a range of temperatures that goes from -190ºC to 600ºC. Additionally, it also has other equipment for the characterization of metals such as pendulums for impact tests, durometers and microdurometers, devices for creep and relaxation tests or chambers for the simulation of corrosion processes.

Fracture and fatigue characterisation

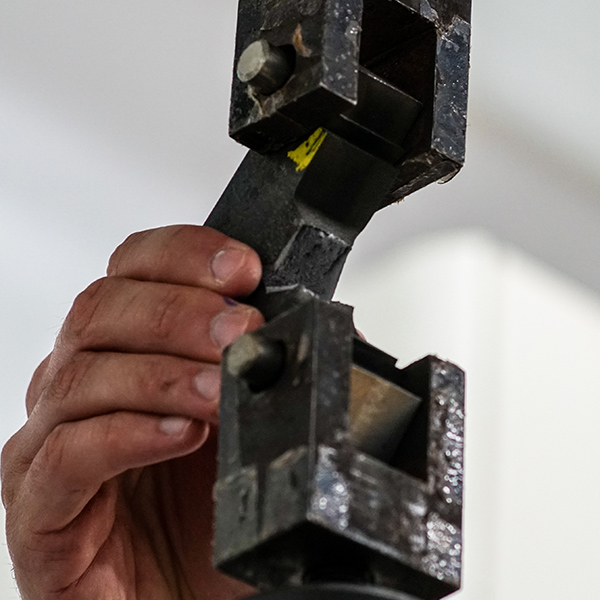

The equipment of LADICIM, together with the expertise of the group, makes fracture and fatigue tests one of the main specialties of the laboratory. The capabilities of the lab make it possible to test large thickness samples (up to 100 mm), although the LADICIM offers the possibility of characterising metallic materials in fracture using more innovative approaches based on the reconstitution of specimens through the methodology of the Master Curve, using material inserts of small dimensions. Regarding fatigue characterization, it is worth to mention that LADICIM has a Zwick / Roell-Amsler 400 HFP 5100 resonance machine that greatly optimizes the length of this type of tests.

Miniature samples

There are situations in which it is not possible to have a sample of material with the dimensions required by conventional testing standards. Under such circumstances, alternative testing techniques that use miniature specimens can be employed. One of these techniques is the Small Punch test which uses plane specimens with a reference thickness of 0.5 mm. LADICIM has been working on this technique -and contributing to its development- for more than 10 years, having been successfully applied for the estimation of tensile, fracture and even creep properties at high temperatures of metallic materials.

Scanning Electron Microscopy (SEM) and optical microscopy

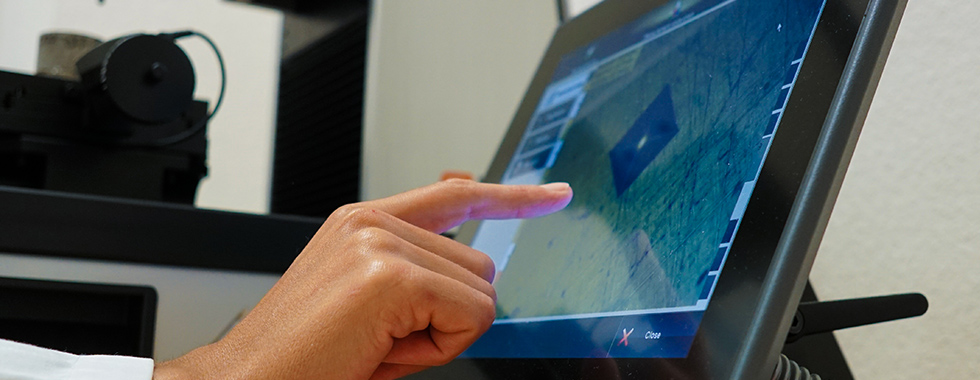

LADICIM has a Zeiss (model EVO MA 15) Scanning Electron Microscope (SEM). The electron acceleration voltage reaches 30 kV and the magnification varies between x7 and x106. It has a microanalysis system based on dispersive energy spectroscopy (EDS) that allows the chemical nature of the analysed materials to be determined. This equipment represents an essential complement to the techniques of mechanical characterization, as it allows the micromechanisms involved in the breaking processes to be studied.

The LADICIM also has an Olympus BX61 optical microscope with a magnification of up to x1000. The optical microscopy used for the characterization of metals allows, among other applications, to identify the phases present in a sample, determine the grain size of the material or discover metal defects on a microstructural scale. All this also contributes to a better understanding of the processes of failure and degradation of materials.