LADICIM participate in Fractesus, the European project that aims to strengthen the safety of nuclear power plants

The results obtained validate the effectiveness of miniature compact specimens for the evaluation of the fracture resistance of nuclear vessels, improving the quantity and quality of the information obtained from the irradiated steel samples

We live surrounded by essential infrastructure for the development of modern life, whose design and operation require a high degree of technical precision. From steel and prestressed concrete bridges capable of responding to growing traffic demands and the effects of climate change, until commercial aircraft prepared to perform transatlantic flights you in a more efficient way. From offshore wind turbines more than 150 meters high with the capacity to withstand wind forces greater than 150 km/h, up to hip implants, made of titanium alloys and coated with biocompatible materials, Designed to withstand millions of load cycles over decades.

The safety and durability of these structures and components depend, critically, on the field of structural integrity, where the ability of materials to withstand operating conditions and avoid failure catastrophic events through advanced monitoring and predictive modeling techniques.

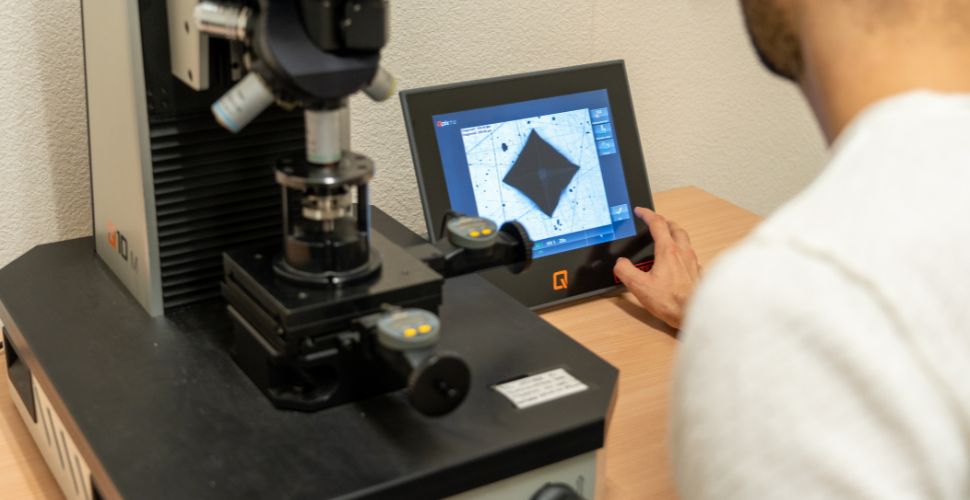

He Laboratory of the Materials Science and Engineering Division (LADICIM) of the University of Cantabria has played an outstanding role during the last three decades in this field of engineering. Currently, he participates in the European project FRACTESUS, which represents a key advance in the field of structural integrity applied to nuclear safety. Its main objective is validate the use of miniature compact specimens (Mini-CT) for the evaluation of the fracture toughness of irradiated vessel steels in nuclear reactors. This is a crucial aspect for the safety and operability of the nuclear sector, especially in the current context of transition towards a more sustainable energy system in Europe.

One of the most notable achievements of FRACTESUS – which has funds from the H2020 program under the Euratom call – is the initial validation of these Mini-CT specimens, which allow multiple toughness values to be obtained from a minimum amount of material, something crucial in the nuclear context, where the availability of irradiated material is very limited.

“Until now, with conventional Charpy specimens, generally used in monitoring programs, we could only obtain a value of the Charpy curve, which in turn served to estimate the fracture resistance of the steel. Now, eight can be machined from each Charpy specimen. Mini-CT specimens, from which many other fracture resistance values of the material can be obtained directly. “This provides a much more precise knowledge of the fracture behavior of the material,” highlights Sergio Cicero, LADICIM’s principal investigator in this project. “In addition, this ability to obtain more data with less material not only improves accuracy, but also reduces the risks associated with the handling of radioactive material”.

Another important milestone is the correlation achieved between the results of the Mini-CT specimens and those obtained with conventional standardized specimens of much larger size. FRACTESUS has demonstrated, after nearly 700 laboratory tests, that the fracture micromechanisms are equivalent in both types of specimens., which reinforces the validity of this technique for its possible adoption in international regulations. “We show that large and small specimens break by the same physical principles. This results key to overcoming the reluctance of nuclear authorities to adopt Mini-CT”, explains Cicero.

More recent nuclear power plant designs have evolved to include not only traditional Charpy test tubes, but also conventional compact test tubes. However, once tested “Instead of obtaining a single fracture toughness value, it is now possible to extract up to 48 Mini-CT specimens from each conventional specimen, multiplying the precision and volume of information available.”. “This represents a significant advance in the ability to analyze and monitor the behavior of materials.”

22 organizations from Europe, Japan, USA and Canada participate in this European project. Among them, prominent institutions like him SCK CEN of Belgium (leader of the initiative), the Mountain biking of Finland, the National Nuclear Laboratory from the United Kingdom or the Central Research Institute of Electric Power Industry (CRABS) from Japan. The results achieved have a significant impact on the nuclear industry, since the implementation of these advanced techniques would help extend the useful life of nuclear power plants by enable more effective and less invasive surveillance programs.

AIn addition to its relevance in the nuclear field, This technology has begun to be applied to other areas, such as structural steels used in civil engineering., thus opening new possibilities for the development of structural integrity.

The progress obtained with FRACTESUS was presented in Santander, on September 10 and 11, within the framework of an International Seminar organized by LADICIM with the support of those responsible for the project. The event was attended by more than 70 international experts.

30 years of experience

More than three decades guarantee LADICIM’s track record in the field of structural integrity. His participation in pioneering projects at European level and collaboration with industrial leaders from around the world It has been essential to develop and validate technologies that ensure the reliability of numerous infrastructures.

Since its beginnings in the 1990s, the Laboratory has been one of the leaders in the research and application of advanced techniques to improve the integrity of multiple structures. One of the first major projects in which he participated was SYNTAP (1996-1999), a pioneering effort in Europe to develop analysis procedures fracture for structural integrity. The Cantabrian laboratory was part of a consortium made up of around twenty partners, including referents as British Steel, UKAEA, Shell, Exxon o GKSS.

“SINTAP represented a fundamental milestone for LADICIM. It not only positioned us as the only Spanish laboratory in a reference consortium, but also laid the foundation for our track record in creating regulations that have had a lasting impact on structural safety in Europe”, explains Federico Gutiérrez-Solana, founder of the Laboratory and main coordinator of research in this area until 2010. “It was the beginning of a line of work that has defined our role in the research and application of structural integrity.”

The success of SINTAP paved the way for the project tribulations (2002-2006), which expanded the scope of the research work to encompass not only the evaluation of the fracture, but also fatigue, creep and corrosion as failure and deterioration mechanisms in materials. Together with large companies and research laboratories in Europe, such as Corus, VTT or British Energy, they developed new European standards for structural integrity evaluation.

For the last 30 years, LADICIM has participated as partner featured in others high-impact European projects (COLDFOSS, FAMEGA, HIPERCUT, INCEFA-PLUS, INCEFA-SCALE). Mostly, oriented to address industrial challenges considered strategic by Europe, whether to improve competitiveness or ensure security in key sectors. In addition, he has developed research for leading companies such as Siemens, Navantia, Celsa or Nuclenor, and has participated in analyzes related to large civil engineering projects, such as the Cádiz Bay Bridge, the largest bridge built in Spain.

The Laboratory has applied its knowledge to a wide variety of materials such as structural steels, keys to the construction of civil infrastructures such as bridges and wind towers; vessel steels, used in nuclear plants, where safety under irradiation conditions is crucial; steels subjected to industrial processes such as electroplating, laser cutting and plasma; and even fixation systems for dental or hip prostheses.

LADICIM’s capacity to adapt to the needs of any sector and offer solutions based on the technical experience acquired During this time it has been key to its positioning in this field of engineering. “The Laboratory is distinguished not only by its work in specific areas, but by its ability to adapt to a wide variety of sectors. We offer a highly specialized service, backed by deep technical knowledge which allows us to solve critical problems of structural integrity in different contexts,” says Gutiérrez-Solana.

Currently, the professors Jose Alberto Alvarez, Sergio Cicero and Diego Ferreño lead the LADICIM research team that addresses complex challenges in the field of structural integrity. The key to staying at the forefront is maintaining a multidisciplinary approach and combining basic research with practical applications.

“Companies and administrations turn to us to perform failure analysis, one of the main applications of structural integrity, to identify causes of breakage of certain components and prevent future problems. The type of structure does not matter, whether aeronautical, nuclear or energy. The fundamental thing is to study and understand how these defects can affect structural integrity of any type of material, emphasizes Professor Sergio Cicero.