LADICIM and Viuda de Sainz strengthen their collaboration for the development of recycled concrete

The Laboratory and the construction company are working together to consolidate the use of recycled aggregates in civil engineering, in line with European regulatory requirements and the challenge of reducing the sector’s environmental footprint

The Laboratory of the Division of Materials Science and Engineering (LADICIM) of the University of Cantabria and the Basque construction company Viuda de Sainz have signed a framework agreement to strengthen their collaboration in the development of recycled concrete. Both entities have been working for years on the characterization and certification of the mechanical behavior and durability of Recycled concretes that incorporate aggregates from construction and demolition waste (CDW). This type of material is key to achieving the European Union’s goal of reusing or recycling at least 70% of CDW. In a national context where the rate of recycled aggregate use barely exceeds 15%, well below the EU threshold, the partnership between LADICIM and the Basque company takes on particular significance.

The main purpose of this sustained collaboration over time is to validate the partial replacement of natural aggregates with recycled materials in concrete intended for structures, ensuring compliance with theactual Structural Code (CE). The technical challenge lies in controlling the intrinsic variability of the secondary material and ensuring that the strength, durability, and steel-concrete adhesion remain within safety margins compatible with its use in buildings and infrastructure.

For this, LADICIM will add It applies advanced experimental methodologies that include standardized compression tests, indirect traction tests, and resistance to humidity cycles, salts, and carbonation, in accordance with the criteria established by the Structural Code and the recommendations of future European legislation.

“Our role is to provide a solid technical foundation and generate confidence based on objective data,” explains the professor Carlos Thomas, responsible for the area of Concrete of LADICIM. “We accurately validate the properties of recycled aggregates to ensure they can be used under real-world construction conditions without compromising structural safety or expected durability.”

The materials evaluated come from the plant Harri Green, owned by Viuda de Sainz and Heidelberg Materials in Bizkaia. This facility is capable of processing 140,000 tons of construction waste and 20,000 tons of steel slag annually, producing recycled aggregates that meet regulatory requirements and they have guaranteed traceability.

“LADICIM’s technical support allows us to move forward with scientific rigor”, points out José Manuel Baraibar, head of R&D of Viuda de Sainz. “We explore new solutions with the security of having a validation that supports our decisions both in the technical field and before the public administration.”

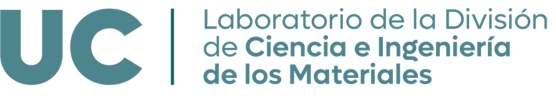

Industrial production and application in real work

The Basque construction company has begun progressively incorporating recycled concrete into its projects, especially in the Basque Country, where regional regulations require at least 20% recycled material in public contracts. Thanks to its collaboration with LADICIM, the company can undertake projects with eco-efficient materials under verified structural guarantees, which contributes to strengthening market confidence, reducing the use of natural aggregates, and lowering carbon dioxide emissions.associated with the manufacture of concrete.

This alliance also includes the development of an industrial doctoral thesis, focused on the structural analysis of these materials and the optimization of dosages to reduce cement consumption.

“Research allows us to explore new compositions, validate hypotheses, and move in a direction consistent with European policies and our sustainability strategy,” adds Baraibar.

Strategic positioning and circular economy

This collaboration strengthens the LADICIM’s role as a leading scientific partner for companies in the construction sector. Their experience in materials characterization and their ability to transform academic knowledge into solutions applicable on an industrial scale are key to facilitating the transition towards more sustainable construction models.

The Laboratory actively participates in strategic initiatives aimed at transforming the sector from its regulatory and technical foundation.He is one of the promoters of the recently established Spanish Association of Eco-Sustainable Concrete, which brings together research centers, companies, and public entities to promote innovation in low-environmental-impact materials. It also collaborates in drafting the Technical Guide for the implementation in Spain of the European regulations on recycled concrete in structures, a prominent document for harmonizing criteria and facilitating their adoption in public and private works.

In an increasingly demanding environment in terms of sustainability and efficiency, this type of alliances between company and university represent an effective way to develop viable, safe technical solutions aligned with the circular economy objectives demanded by Europe.

More news

LADICIM consolidates progress of the INTELEST project in AI for sustainable energy and transportation

The University of Cantabria Laboratory advances in the development of predictive models for nuclear safety, offshore wind power, and the maintenance of high-performance railway infrastructure,

The University of Cantabria awards LADICIM its proposal for sustainable concrete for the nuclear industry

The GreenCosmos project, recognized in the UC Solutions 2025 call, proposes an innovative solution for the energy infrastructure of the future, combining security and a

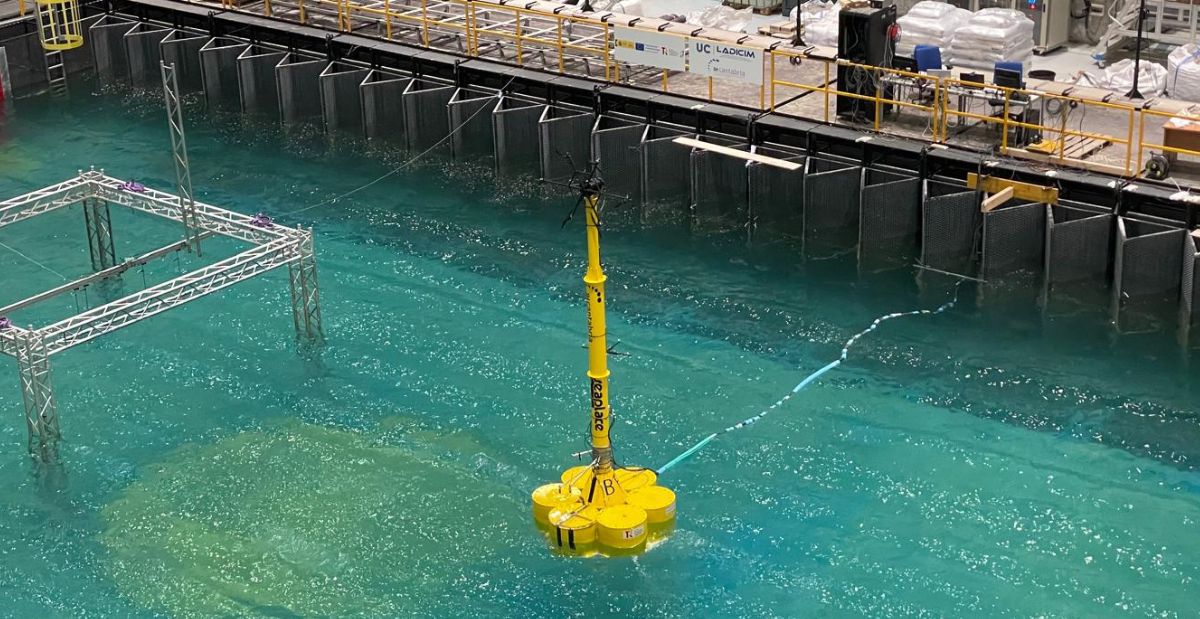

LADICIM is participating in the development of a new generation of floating concrete platforms for offshore wind energy

The ISOBARA project, in collaboration with SEAPLACE and IHCantabria, designs industrializable solutions to reduce costs in floating wind farms The energy transition toward a low-carbon