LADICIM participates in European project that applies AI to extend the life of nuclear power plants

ENTENTE, coordinated by CIEMAT, lays the groundwork for Materials Informatics to more accurately predict reactor vessel degradation and enhance the safety of its long-term operation

In a world marked by the challenge of climate change and the need for low-carbon energy sources, nuclear power generation can play a fundamental role. Provided it overcomes the challenge of its aging infrastructure, as many of the power plants currently operating in Europe and the United States are approaching the end of their original design life, typically 40 years. Extending their operation to 60, 80, or even 100 years—a strategy already being pursued by reference countries such as the United States and France—is presented as a viable and necessary option to maintain a stable, emissions-free energy source. However, for this extension to become a reality, it is essential to scientifically guarantee the safety and integrity of its critical components for additional decades.

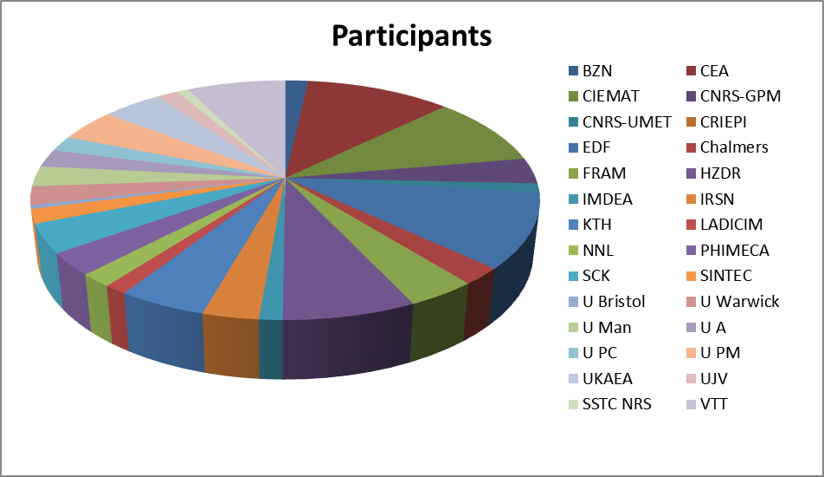

In response to this challenge, the European project ENTENTE investigates how the most advanced data management and artificial intelligence tools can revolutionize the way we understand and predict the aging of nuclear materials. Coordinated by the Center for Energy, Environmental and Technological Research (CIEMAT), the project has involved the participation of the Materials Science and Engineering Division Laboratory (LADICIM) of the University of Cantabria, along with 25 other partners from 12 countries, including nuclear powers such as France and Japan and collaborators from Ukraine.

The Achilles' Heel

One of the biggest technical challenges for Long-Term Operation lies in the reactor pressure vessel, a gigantic steel structure, often up to 60 feet (20 meters) tall, that houses the radioactive core. This component cannot be replaced and is subjected to extreme conditions: high pressure, high temperature, and, above all, a constant bombardment of neutrons from nuclear reactions. “These neutrons, upon impacting the crystalline structure of the steel, displace the atoms from their original position, creating defects on a microscopic scale,” explains Marta Serrano, head of the Materials for Energy Division at CIEMAT and coordinator of the ENTENTE project.

Over the years, the accumulation of these defects modifies the mechanical properties of the steel. The most worrying phenomenon is neutron irradiation embrittlement: the material loses its ability to deform plastically (its ductility) and becomes more susceptible to fracture. Accurately predicting how this embrittlement will evolve over 60 or 80 years is crucial to ensuring the vessel maintains its structural integrity. “All this study on embrittlement is fundamentally to ensure safe operation,” stresses Dr. Serrano. “The nuclear sector works with enormous safety margins, and we need the scientific knowledge to back up these long-term assessments.”

A Paradigm Shift

Traditionally, the study of material degradation has been based on laboratory experimentation and the development of analytical models based on known physics. But this approach has limitations. “Being very good experimentalists and generating high-quality data is fundamental, but it is no longer enough,” notes Marta Serrano. “This method is too slow to qualify new materials or to fully understand all the complex degradation mechanisms. We needed to accelerate knowledge.”

This is where ENTENTE proposed a paradigm shift, embracing what the team calls Materials Informatics. The idea is to complement the solid experimental foundation with advanced digital tools. “Understanding the degradation of materials in service, but not in the classical way,” adds Dr. Serrano.

This new philosophy is based on two fundamental pillars that ENTENTE set out to develop:

- Advanced Data Management: Generating data, even if high-quality, is no longer enough given the current complexity and volume. It is crucial to organize it systematically, structure it in well-designed databases, and ensure it is easily accessible. This rigorous management is essential for joint analysis, avoiding duplication, and extracting meaningful knowledge.

- Hybrid Models: Leveraging structured data to train and validate advanced predictive models, particularly those based on Artificial Intelligence (AI) and Machine Learning (ML). These powerful tools can decipher the complex interrelationships between multiple factors that affect embrittlement, offering more accurate predictions than conventional methods.

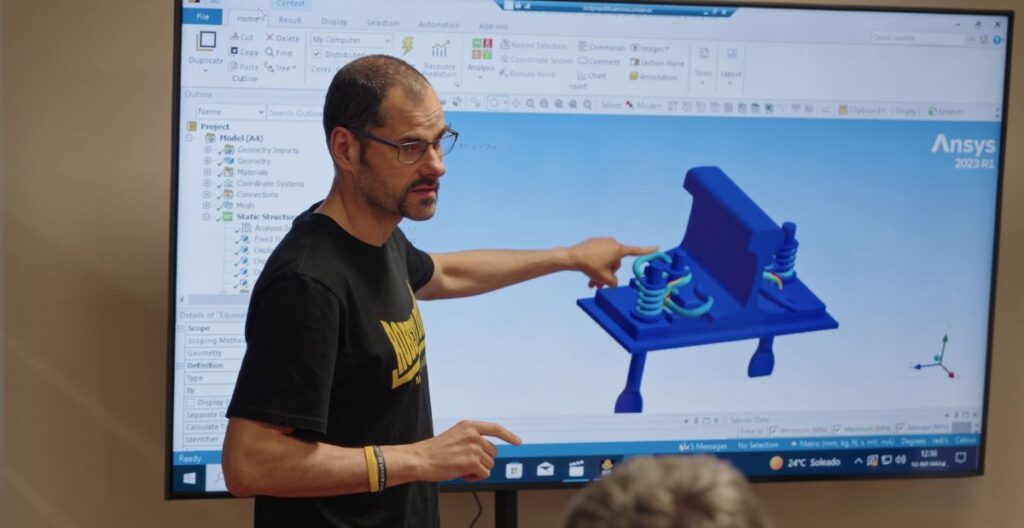

Diego Ferreño, a professor at the University of Cantabria, researcher at LADICIM, and one of the leaders in the development of AI models in ENTENTE, highlights the importance of open and collaborative data management. “The idea is that the data generated should not remain isolated on one computer, but rather be accessible, interoperable, and reusable by the entire international scientific community. Only then can we truly accelerate collective knowledge.”

Algorithms for Safety

With this vision, the ENTENTE team got to work. The heart of the project was the design and implementation of a specific database on irradiation embrittlement. “We didn’t start from scratch,” clarifies Dr. Ferreño. “We relied on existing databases, such as Plotter, compiled for years by Dr. Mark Kirk, also an ENTENTE partner, which brings together information from nuclear power plant surveillance programs worldwide.”

But building a modern and functional database was a challenge in itself. It involved not only collecting scattered data from previous projects and generating new high-quality experimental data but also defining a common structure and language. “One of the great challenges was working with the IT engineers from the Polytechnic University of Madrid to define the data ontology,” explains Dr. Serrano. “We needed more than a year to agree on what each technical term meant and how to structure it so the computer system could correctly understand and relate it. It was a necessary cultural clash between both disciplines.”

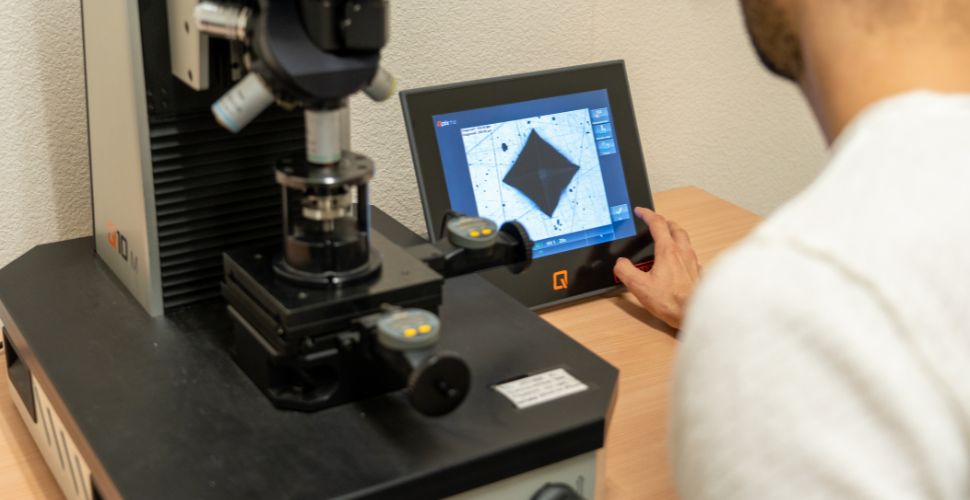

Once the database was established, the LADICIM team, led by Professor Ferreño, focused on developing and applying Machine Learning algorithms to predict the change in the ductile-to-brittle transition temperature, the standard metric for quantifying embrittlement. Using techniques like Gradient Boosting, they trained models with the available data, including key variables such as the steel’s chemical composition, irradiation conditions, and the type of steel product.

The results are promising. “The Machine Learning models proved to be significantly more accurate than traditional analytical models,” states Dr. Ferreño. In the tests performed, the Gradient Boosting model achieved a reduction in the mean squared error of approximately 21% compared to the standard model. “More importantly,” he adds, “we observed a notable reduction in large errors, those predictions that deviated greatly from the experimental value, which is critical from a safety perspective.”

Artificial Intelligence to Unveil New Physics

The work didn’t stop at creating a predictive ‘black box.’ A fundamental part of the Materials Informatics approach is using AI not only to predict but also to better understand the underlying physical phenomena. The team applied advanced model interpretability techniques to “interrogate” the algorithm and understand which variables it considered most important and how they influenced the prediction.

“The results were fascinating,” assures Professor Ferreño. “On one hand, the model autonomously identified that Copper and neutron fluence were the most determining factors in embrittlement, something that materials physics was already well aware of. This gave us confidence that the model was capturing the correct physics.”

In addition to these advances, ENTENTE also explored other innovative methodologies, such as the KNT (K-Nearest Travelers) model, developed at LADICIM. This approach is based on Dr. Ferreño’s personal experience as a runner and his perception that very different runners (by age, sex, or stature) can, nevertheless, have very similar racing careers. This analogy translates the idea of similarity between time series to the technical field, which is the concept underlying the KNT model.

Thus, it seeks to predict the future behavior of a material based on the complete “embrittlement history” (a time series) of other materials that have shown a similar evolution, rather than relying only on static properties like chemical composition. Preliminary results show that KNT, especially when combined with Machine Learning, can surpass the accuracy of other methods.

The LADICIM Experience

LADICIM’s participation in a project of ENTENTE’s complexity is not accidental. The University of Cantabria laboratory has a long and recognized track record in the field of materials science and engineering, structural integrity, and computational modeling. Its experience in analyzing the mechanical behavior of materials under extreme conditions, combined with its growing specialization in Data Science and Artificial Intelligence techniques applied to engineering problems, positions the Laboratory as a strategic partner in cutting-edge European research.

Although the ENTENTE project has formally concluded, its legacy endures. It has laid the methodological and philosophical foundations for a new way of approaching nuclear materials science, integrating data, experiments, and advanced models in a way that is unprecedented in this field. “We have shown that this hybrid approach works, allowing us not only to predict better but also to understand better,” summarizes Diego Ferreño. In fact, the collaboration and the ENTENTE approach continue and are expanding in the new European project Connect-NM, also coordinated by CIEMAT through Marta Serrano. This program will finance European research in nuclear materials over the coming years, ensuring that data management and advanced models remain a central part of the investigation.

Más Noticias

LADICIM Participates in Fractesus, the European Project Aiming to Enhance Nuclear Power Plant Safety

The results obtained validate the effectiveness of miniature compact specimens for evaluating the fracture resistance of nuclear reactor pressure vessels, improving both the quantity and

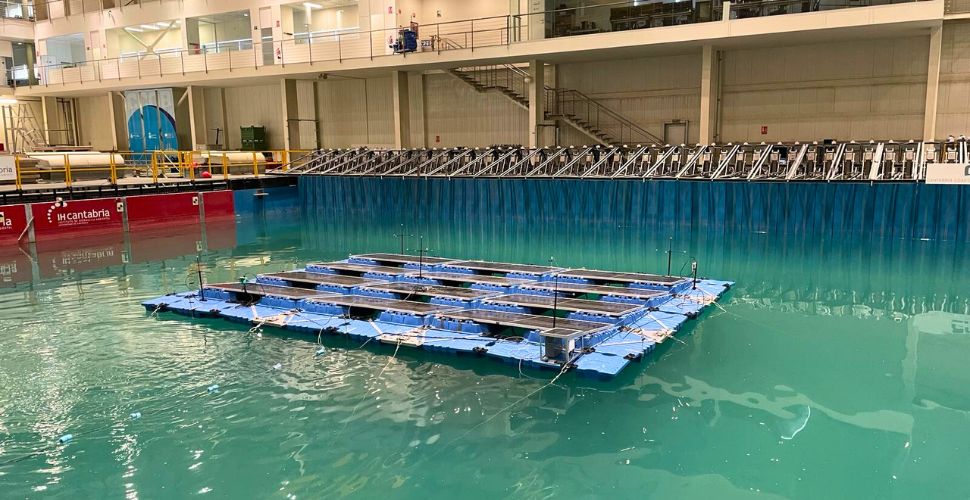

LADICIM Collaborates with Isigenere and IHCantabria to Drive New Designs and Incorporate Advanced Materials in Floating Solar Structures

The ‘SolEtAqua’ project, which also involves the University of Jaén, aims to develop new methodologies to predict the dynamic behavior of floating photovoltaic plants and

LADICIM Leads the Cantabrian Project Applying AI to Reduce Emissions in Industry, Energy, and Transport

The INTELEST project, funded by the Government of Cantabria with European funds, involves the collaboration of companies such as GSW and Rocacero, research centers like