LADICIM consolidates progress of the INTELEST project in AI for sustainable energy and transportation

The University of Cantabria Laboratory advances in the development of predictive models for nuclear safety, offshore wind power, and the maintenance of high-performance railway infrastructure, transferring high-impact knowledge to the Cantabrian industry

Artificial Intelligence (AI) stands as an effective and substantial tool to face the technological challenge posed by the transition towards a decarbonized and sustainable economy. This technology is essential for supporting process optimization, the design of new materials, and safeguarding critical infrastructure. In this context of innovation and sustainability, the Materials Science and Engineering Laboratory (LADICIM) at the University of Cantabria has promoted the INTELEST project, coordinated by its founder, Professor and Emeritus Chair Federico Gutiérrez-Solana. Its objective is to apply AI to achieve significant progress in innovation and knowledge transfer in strategic sectors for society, and specifically for Cantabria.

Funded by the Department of Industry (Consejería de Industria) of the Government of Cantabria (Gobierno de Cantabria) through the FEDER 2021-2027 program (TCNIC line), INTELEST has proven to be a driver of knowledge transfer. After successfully completing its first line of research, focused on optimizing energy consumption in steel production in collaboration with Global Steel Wire (GSW), the project is steadily advancing in its other three lines of research, centered on nuclear energy, marine renewables, and rail transport. The work developed throughout 2025 has represented a qualitative leap in the hybridization of numerical simulation, advanced experimentation, and machine learning (ML).

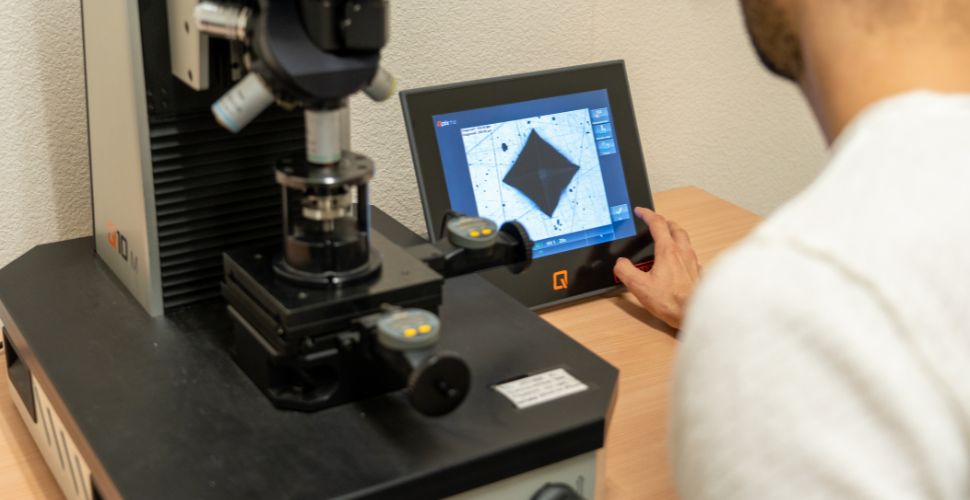

Nuclear Safety: The GPS for Material Behavior

One of the project’s most complex work lines, coordinated by Professor and Chair Diego Ferreño, focuses on predicting the embrittlement of steels in nuclear reactor pressure vessels. Ensuring the integrity of these components is crucial for long-term operation and life extension of nuclear power plants.

Traditional analytical models, though robust, have limitations in predicting material behavior under decades of neutron irradiation. “Traditional models fall short. We needed a way to group materials not by ‘who they are’ or exactly what they are made of, but by ‘how they behave’ under irradiation conditions,” explains Professor Ferreño. “And that is exactly what we have achieved.”

The major breakthrough achieved in 2025 is the consolidation and implementation of the KNT (k-nearest travelers) model. This innovative approach moves away from conventional machine learning algorithms, which group data by input variables (chemical composition), and proposes a dynamic aggregation based on the material’s neutron embrittlement behavior, although this depends on the composition, the processing, the resulting microstructure of the material, and the operational functionality variables.

To achieve this, the LADICIM team uses the PLOTTER database, one of the most complete in the world and to which the laboratory has access thanks to its international collaborations with entities such as ASTM, EPRI, and CIEMAT. The key parameter of the KNT model is the Area Under the Curve (AUC) of the Embrittlement Trend Curve (ETC). “The underlying hypothesis is that materials with similar AUC values exhibit analogous behavior, regardless of their exact composition. It is a kind of behavioral fingerprint,” specifies Dr. Ferreño.

The team has already identified 821 “families” of materials in the database. The KNT model identifies “nearest travelers” (materials with similar AUC) to enrich the study of a target family, performing a joint fit.

The hybridization of technologies is total. The project is integrating machine learning algorithms to substitute analytical components with data-driven approximations, for example, using ML to predict the ETC curve instead of using the ASTM E900 standard, which has improved the regression metrics.

In parallel, an exploratory line has been initiated with Physically Informed Neural Networks (PINNs). This technique incorporates physical knowledge (the ASTM E900 standard itself) directly into the neural network’s loss function, restricting its solution space to ensure physical consistency. To support validation, an interactive visualization application has been developed, allowing the KNT model results to be explored intuitively, facilitating knowledge transfer to both the scientific community and companies in the nuclear sector.

Sustainable Concrete in Marine Environments

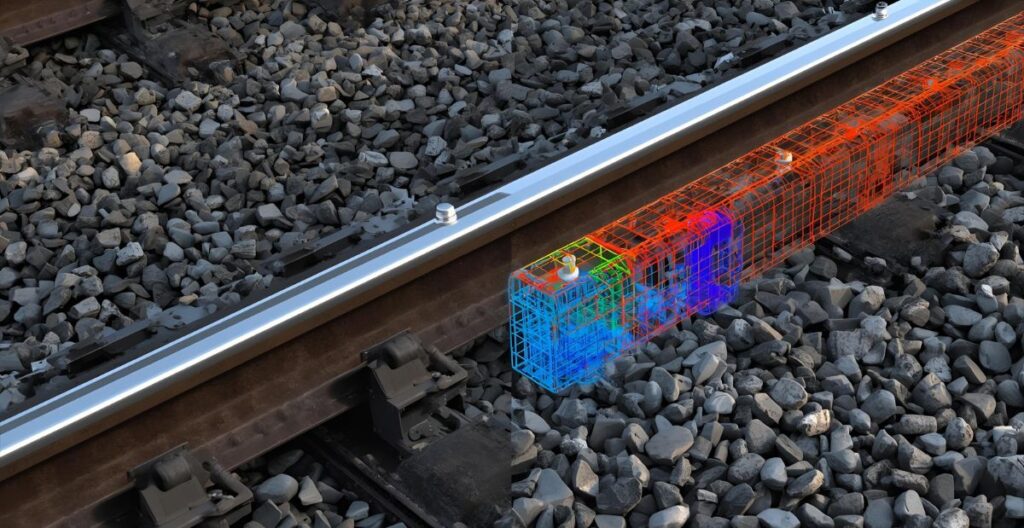

Another line of INTELEST research addresses a new pillar of the energy transition: floating offshore wind power. Traditional steel structures face challenges of corrosion, cost, and maintenance in the aggressive marine environment. The alternative explored by LADICIM, in collaboration with the precast company Rocacero, is high-performance, low-carbon-footprint concrete.

This year’s work has focused on CEM III, a type of blast-furnace slag cement that stands out for its sustainable properties, as it presents a significantly lower carbon footprint and lower heat of hydration, which reduces the risk of cracking in large structures. The first major milestone has been demonstrating its scalability, as an industrial batch has been successfully executed at Rocacero’s facilities, showing a high correlation between laboratory and industrial properties. “Being able to demonstrate that we can manufacture it at this scale, in a real plant, with the same results as in the laboratory is the validation the industry needs for its application, promoting the transfer process,” highlights Professor Isidro Carrascal, leader of this work line.

The second pillar of the work developed in 2025 has been the advanced characterization of durability. To this end, 20 test specimens of different geometries have been deployed in the marine facilities of El Bocal (Cantabria), managed by the CTC Technology Center (Centro Tecnológico CTC) in collaboration with the Spanish Institute of Oceanography (Instituto Español de Oceanografía). These specimens are subjected to waves at different depths, evaluating the effect of partial immersion and the splash zone. In parallel, accelerated tests have been performed in a salt spray chamber to correlate natural degradation with laboratory degradation and to establish aging models in an appropriate time frame.

In the field of AI, the team has developed a local behavior model based on a Design of Experiments. By introducing variables such as the water/cement ratio, this advanced statistical model predicts with high precision key parameters such as compressive strength, fresh state consistency, water absorption, or the chloride diffusion coefficient. “It is, in practice, a digital twin of the mixture design, which drastically optimizes and reduces the experimental process,” notes Professor Carrascal.

Finally, a thermal model of the concrete has been developed and validated using the Finite Element Method (FEM). This model, calibrated with instrumented blocks in the laboratory, is essential to prevent deterioration due to cracking caused by thermal behavior. The results confirm a significant difference in heat of hydration between CEM I and CEM III, the latter being notably lower, which reduces the risk of internal stresses.

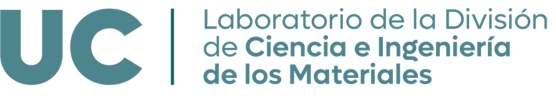

The Digital Twin of the Railway Track

The fourth line of INTELEST research focuses on transport, specifically on the predictive maintenance of high-speed railway infrastructure. The goal is to move from reactive or preventive maintenance to predictive maintenance, optimizing costs and increasing safety.

This year’s work, coordinated by Professor and current LADICIM director José A. Casado, has consolidated a comprehensive methodological framework that combines laboratory experimentation, advanced numerical simulation (FEM), and Artificial Intelligence (Machine Learning (ML)). The focus has been on base plates, elastomeric components of the rail fastening system, track fastenings, and the track infrastructure as a whole.

“We are combining the best of two worlds: the physical rigor of finite element simulation and the statistical efficiency of machine learning,” points out Professor Casado. “FEM gives us high-fidelity data, and ML learns to ‘read’ that data for us, giving us quick predictions about the state of the track.”

The methodology has been structured into five complementary blocks. First, laboratory tests were conducted on deteriorated plates due to different mechanisms, such as mechanical fatigue, hydrocarbon degradation, and exposure to ultraviolet light, to understand how they age. Second, with this data, ML predictive models were developed capable of estimating the dynamic stiffness and loss of performance of the plates.

In parallel, two types of numerical models were created: a detailed, three-dimensional FEM model of the fastening system that includes all the non-linearities of the clips and bolting; and a more simplified FEM model of a track section, designed for repeated executions and sensitivity analysis.

The key innovation lies in the combination of FEM and ML. The detailed FEM model is used to generate a large, high-quality database corresponding to thousands of load, geometry, and material scenarios. Subsequently, ML algorithms are trained with this virtual database to identify patterns and relationships. “In this way,” concludes Dr. Casado, “the system combines the physical rigor of real behavior with the efficiency of analytical methodologies and statistical learning, allowing for fast and reliable predictions.”

The transferability of these results is immediate, offering infrastructure administrators, such as ADIF, and sector organizations, such as the MAFEX association, a practical tool for the early identification of failures, the optimization of component replacement, and cost reduction. It is a decisive step towards the creation of a digital twin of the track.

A Consolidated Transfer Trajectory

The progress of INTELEST is based on the knowledge transfer strategy that LADICIM has cultivated for over four decades of research. In the last five years alone, the laboratory’s researchers have published more than 100 articles indexed in theJournal Citation Reports (JCR) related to these work lines.

Furthermore, the integration of Artificial Intelligence across all its lines of research, enhanced by projects like INTELEST, reinforces the laboratory’s capacity to serve the industry and generate a positive impact.

The INTELEST project is therefore consolidated as a strategic initiative, demonstrating how the application of cutting-edge technologies, alongside disruptive knowledge, can optimize industrial processes, improve the safety of critical infrastructure, and develop more sustainable materials. The advancements in nuclear safety, offshore wind power, and rail maintenance not only position LADICIM as a benchmark in the hybridization of simulation and AI but also directly contribute to enabling the improvement of the competitiveness of Cantabria’s industrial fabric and the global fight against climate change.

This entity has received co-financed aid from the European Regional Development Fund through the FEDER Operational Program 2021-2027 of Cantabria by means of the subsidy line ‘Aid for research projects with high industrial potential from excellence technology agents for industrial competitiveness TCNIC’.

Más Noticias

LADICIM Participates in Fractesus, the European Project Aiming to Enhance Nuclear Power Plant Safety

The results obtained validate the effectiveness of miniature compact specimens for evaluating the fracture resistance of nuclear reactor pressure vessels, improving both the quantity and

LADICIM Collaborates with Isigenere and IHCantabria to Drive New Designs and Incorporate Advanced Materials in Floating Solar Structures

The ‘SolEtAqua’ project, which also involves the University of Jaén, aims to develop new methodologies to predict the dynamic behavior of floating photovoltaic plants and

LADICIM Leads the Cantabrian Project Applying AI to Reduce Emissions in Industry, Energy, and Transport

The INTELEST project, funded by the Government of Cantabria with European funds, involves the collaboration of companies such as GSW and Rocacero, research centers like