LADICIM collaborates in the Freedom project to improve the safety of nuclear power plants

The research, coordinated by CIEMAT, delves into the use of mini-CT specimens and Artificial Intelligence to characterize the integrity of the reactor pressure vessel in the face of the materials aging challenge

Extending the useful life of nuclear power plants is not only a matter of energy strategy; it is, above all, a major engineering challenge. Materials age, they degrade, and knowing with certainty until when they will maintain their integrity requires millimeter precision. Aware of this scenario, and following the resolution of its competitive call at the end of 2025, the Nuclear Safety Council (CSN) has launched the FREEDOM project. In this initiative, coordinated by the CIEMAT under the leadership of Dr. Marta Serrano, the Laboratory of the Materials Science and Engineering Division (LADICIM) of the University of Cantabria takes on a leading role: developing the technology necessary to assess the health of the reactor pressure vessel even when there are barely any physical samples to analyze.

The biggest headache when evaluating the safety of an aging reactor in Long-Term Operation (LTO) is the lack of “witnesses” or “surveillance specimens”. It is often unfeasible to have irradiated material specimens from the vessel to subject them to traditional strength and toughness tests. Simply, there is not enough material.

Advanced simulation and digital twins

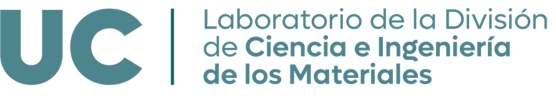

The role of the LADICIM is key in the project methodology, leading two of the four work packages. In the field of simulation, the University of Cantabria team, headed by Professor Diego Ferreño, develops an advanced numerical framework to quantify the statistical dispersion of the results.

Through three-dimensional finite element models, UC researchers reproduce the geometry and ductile-brittle transition phenomena, incorporating Beremin-type local fracture micromechanical models. Furthermore, massive campaigns of virtual Monte Carlo tests are carried out, which allow evaluating how geometric or thermal uncertainties influence the results. This is essential for defining new validity criteria and improving current regulatory recommendations.

The project is based on a solid experimental foundation that transcends borders. Alongside CIEMAT and LADICIM, the consortium includes the participation of the German research center Helmholtz-Zentrum Dresden-Rossendorf (HZDR), adding a European dimension to the research.

The experimental campaign is exhaustive. The team will analyze reference vessel materials, in addition to a ferritic weld specifically manufactured by submerged arc welding for this project. This phase includes the machining of mini-CT specimens and the execution of a minimum of 20 tests per material at different temperatures, applying maximum likelihood statistical analysis based on the Master Curve.

Applied Artificial Intelligence

FREEDOM does not start from scratch, but builds upon previous large-scale European initiatives, such as the ENTENTE project. On that occasion, the consortium already laid the groundwork for what is called Materials Informatics, combining experimentation with digital tools.

This approach links with the strategy validated in ENTENTE, where it was already demonstrated that hybrid models could surpass traditional analytical models in accuracy. As Professor Ferreño points out regarding the use of these technologies: “Machine Learning models proved to be significantly more accurate [… ] we observed a notable reduction in large errors, those predictions that deviated greatly from the experimental value, which is critical from a safety point of view.”

LADICIM’s participation in FREEDOM reaffirms its position as a strategic partner in nuclear research. The laboratory has a recognized track record in the analysis of mechanical behavior under extreme conditions and a growing specialization in Data Science. The granting of this project, endowed with competitive funding from the CSN, represents recognition of the consortium’s scientific and technical excellence.

Más Noticias

LADICIM collaborates on the guide to implement the European standards for recycled concrete in structures in Spain

The goal is to provide precise recommendations to optimize the design and execution of structures using recycled concrete, contributing to the transition toward more environmentally

LADICIM and IFCA use AI to automate graphite classification in iron foundries

Using convolutional neural networks, the new system identifies graphite morphology with high precision, overcoming the limitations of manual analysis and enabling more rigorous and efficient

LADICIM and GSW Join Forces to Optimize Steel Quality Through Residual Hydrogen Control

The H2ALAM project investigates how to improve the strength and durability of this material by regulating the levels of the chemical element during its manufacturing