LADICIM aims to fortify floating wind with more durable, safer and more sustainable platforms

In a consortium with SEAPLACE, IHCantabria, and UPM, the Cantabrian laboratory will lead the development of green and self-healing concretes to optimize the CROWN floating platform

Europe’s race for energy decarbonization has ceased to be a promise and has become an industrial and technological necessity. With the goal of installing 300 GW of offshore wind energy by 2050, the sector inevitably looks toward deep waters, where the wind resource is greater, and the technical challenges are immense. In this highly complex scenario, the Materials Science and Engineering Division Laboratory (LADICIM) of the University of Cantabria takes a new step forward with its participation in ISOTACA, an ambitious research project awarded in the latest call for Public-Private Collaboration from the Ministry of Science, Innovation, and Universities.

Led by the engineering firm SEAPLACE, the ISOTACA project (‘Research on floating wind platforms for the development of resilient solutions to the marine environment’) is born as the natural and necessary evolution of the successful ISOBARA project. While the latter laid the foundation for the structural viability of concrete platforms, ISOTACA seeks operational excellence: perfecting the design to be more durable, more ecological, and more stable against the ocean’s battering.

To address this multidisciplinary challenge, the original consortium formed in ISOBARA by SEAPLACE, LADICIM, and IHCantabria has been strengthened with the incorporation of the Polytechnic University of Madrid (UPM) through its research group CEHINAV, adding new capabilities in experimental hydrodynamics.

Towards the Concrete of the Future: Circular and Smart

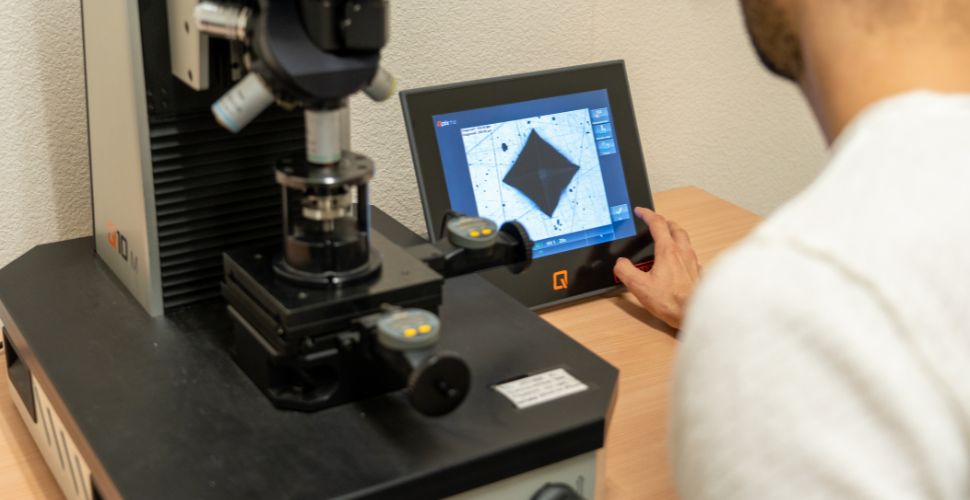

LADICIM’s role in this initiative is fundamental and focuses on materials science pushed to its technological limit. The goal is no longer just to build a platform that floats, but to do so with a reduced carbon footprint and an extended service life. To this end, researchers at the University of Cantabria will work on the design of circular concretes, integrating industrial byproducts.

According to Professor Diego Ferreño, a LADICIM researcher linked to the project, the challenge is twofold: “We are seeking to valorize industrial waste to reduce the environmental impact of construction, but without compromising mechanical resistance one bit.” Furthermore, the laboratory will explore technological frontiers such as self-healing concretes and the use of non-metallic reinforcements. “We are investigating the material’s ability to seal its own microcracks in a marine environment, which is key to ensuring watertightness and reducing maintenance costs offshore,” Professor Carlos Thomas, LADICIM’S Quality Director, specifies.

The project includes an extensive experimental campaign at LADICIM’s facilities to analyze how curing in seawater and thermal gradients affect the concrete at early ages, simulating real-world manufacturing conditions in port and operation in the ocean.

Taming the Sea: Sloshing and New Mooring Systems

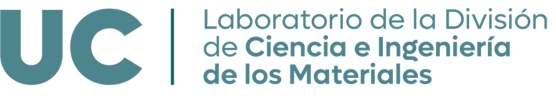

While LADICIM fortifies the structure at the material level, the rest of the consortium will address the dynamic challenges. The CROWN platform, patented technology by SEAPLACE, stands out for its capacity for industrialized concrete construction, similar to harbor caissons. However, its operation in open waters involves complex challenges.

One of the central focuses of ISOTACA is to mitigate the phenomenon of sloshing (the violent movement of water inside ballast tanks), which can destabilize the turbine. This is where UPM contributes its expertise, developing numerical and experimental models to predict and dampen these internal loads.

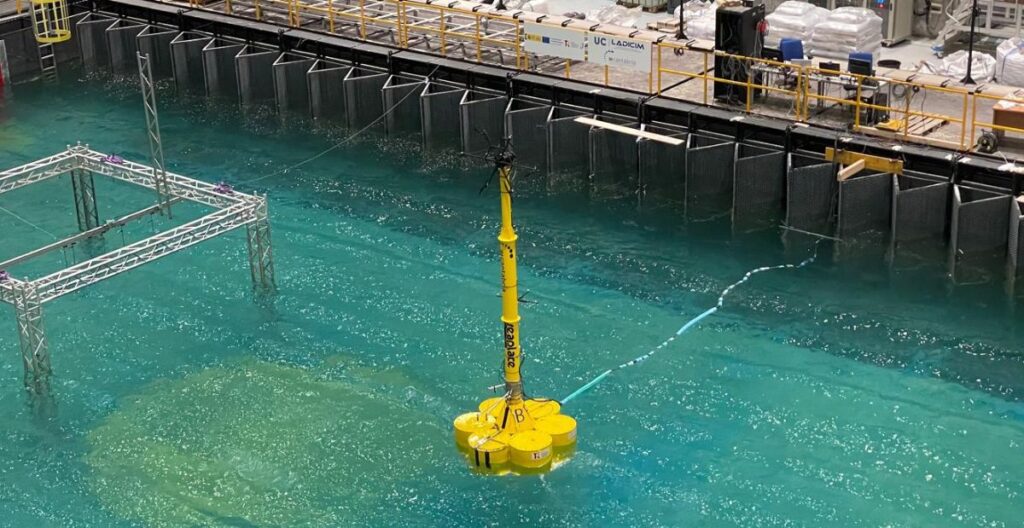

In parallel, IHCantabria will focus on external hydrodynamics. Its researchers will design passive solutions, such as “botaolas” (wave breakers) inspired by port engineering, to prevent waves from flooding the platform deck (a phenomenon known as green water). Additionally, they will develop innovative methodologies to analyze mixed mooring systems, combining chains with synthetic nylon lines. These lines, while effective, exhibit complex nonlinear behavior (hysteresis) that must be precisely modeled to ensure the platform maintains its position during extreme storms.

Avant-Garde and Technological Transfer

LADICIM’s participation in ISOTACA reaffirms its position as an international benchmark in the characterization of materials for hostile environments. With facilities spanning over 3,000 m² and ENAC accreditation, the University of Cantabria laboratory continues to demonstrate its capacity to transfer high-level academic knowledge into tangible industrial solutions.

The project, which will be developed over 36 months, aims to eliminate the last technical barriers to the massive deployment of floating wind. By combining the circular economy with precision naval engineering, ISOTACA not only promises cleaner energy technology but also positions Spanish engineering and its research centers at the forefront of the European Blue Economy.

Más Noticias

LADICIM Participates in Fractesus, the European Project Aiming to Enhance Nuclear Power Plant Safety

The results obtained validate the effectiveness of miniature compact specimens for evaluating the fracture resistance of nuclear reactor pressure vessels, improving both the quantity and

LADICIM Collaborates with Isigenere and IHCantabria to Drive New Designs and Incorporate Advanced Materials in Floating Solar Structures

The ‘SolEtAqua’ project, which also involves the University of Jaén, aims to develop new methodologies to predict the dynamic behavior of floating photovoltaic plants and

LADICIM Leads the Cantabrian Project Applying AI to Reduce Emissions in Industry, Energy, and Transport

The INTELEST project, funded by the Government of Cantabria with European funds, involves the collaboration of companies such as GSW and Rocacero, research centers like