LADICIM and GSW Patent a Clamping System to Prevent Specimen Breakage in Tensile Tests of Metallic Materials

The Laboratory of the University of Cantabria and the company specialized in wire rod production have designed a jaw adapter that significantly reduces the pressures experienced by these devices during this type of quality control tensile testing.

Researchers at LADICIM, in collaboration with engineers from Global Steel Wire (GSW), have patented an innovative solution to prevent specimen breakage during tensile-compression testing of metallic materials. The solution consists of an adapter that prevents failure in the gripping zone of the specimen to the jaws—a recurring problem that poses a significant challenge in ensuring the quality and efficiency of these tests.

This marks the 12th patent developed by LADICIM since 2003.

In this case, the researchers from the Laboratory of Materials Science and Engineering at the University of Cantabria addressed a challenge faced by GSW regarding quality control of the wire rod they manufacture: guaranteeing the integrity of constant-section specimens required for tensile testing, which is essential for maintaining final product quality.

Conducting these tests is challenging because high pressures must be applied on the jaws to prevent specimen slippage. This generates elevated stresses at the ends, increasing the risk of fracture in that region—especially at the contact point with the jaw.

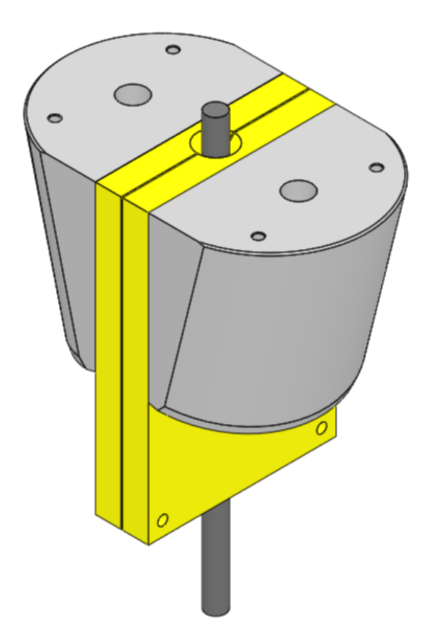

This innovative, tailor-made clamping system minimizes the stresses applied at the ends of the cylindrical constant-section specimen. “The design includes a pair of hardened steel plates at each end of the specimen, each machined with a cylindrical groove of calibrated diameter that houses the specimen. This setup ensures excellent contact surface and an appropriate distribution of the applied forces,” explains Diego Ferreño, professor at the University of Cantabria and researcher at LADICIM.

A crucial aspect of this solution is protecting the specimen from direct contact with the testing machine jaws, which often have rough surfaces that could damage the specimen. “In contrast, the grooves in the plates have been carefully polished using precision machining to provide a smooth contact surface. Additionally, the plates are longer than the jaws, producing a gradual transition of stresses experienced by the specimen both in the jaw region and the free span between them.”

Another key component of the system is a validated procedure to maximize friction between the specimen and plates, thus reducing the pressure applied on the jaws as much as possible. This is achieved by impregnating the specimen ends with industrial oil, over which a small amount of corundum powder is applied.

A Solution for Other Companies

The experimental results derived from this two-year research project have demonstrated the system’s effectiveness. Over 1,000 tensile tests were conducted, yielding satisfactory results in approximately 97% of cases. The work shows that it is possible to apply a pressure of only 15 bar on the jaws, compared to the roughly 70 bar normally required to prevent slippage.

“From a practical standpoint, we have successfully developed a transfer project with significant impact on GSW’s operations. Moreover, this solution could benefit other companies we collaborate with, as these types of tests are very common in the industry and unexpected breakages in the jaw area are a widespread concern,” notes Ferreño.